GENESIS CUSTOM ORDER MACHINES

Call for Price

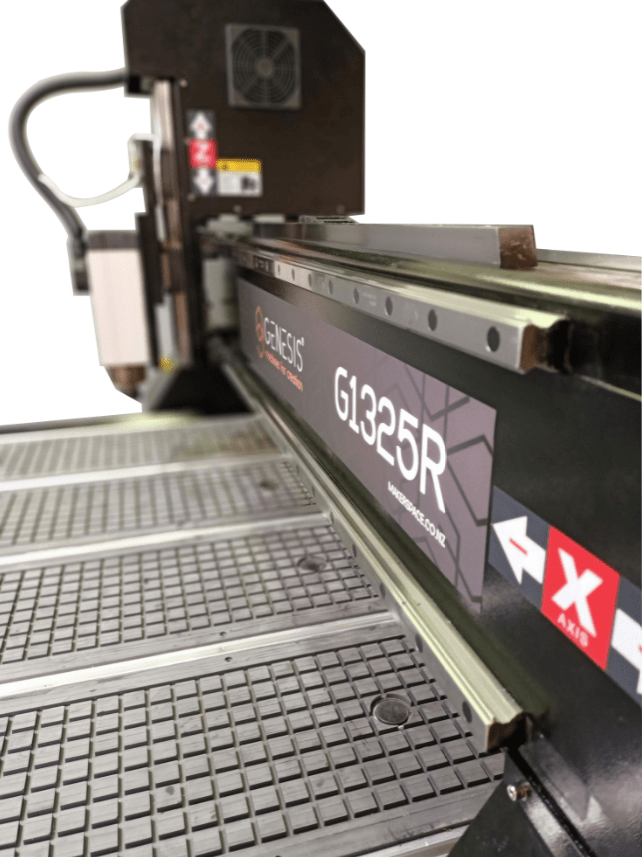

Our commercial grade 1300x1300mm and larger CNC routers feature powerful drive systems, developing much faster speeds than our smaller entry level machines, and quietly. Thanks to the precision helical rack & pinions together with quality stepper/servo drive motors in X-axis and Y-axis and stepper/servo ball-screw type drive for the Z-axis (spindle up/down).

The spindle dust hood/cover is manually removable on single tool machines and pneumatically actuated on ATC machines.

Here’s a link to our Facebook page showing a video of a G2513RATC 4-tool changing Router.

Our range of CNC routers are the perfect solution for 2D and 3D machining for both entry level and commercial production applications of all shapes & sizes. With standard features like a 300mm Z axis travel (approx. 200mm machinable height) & combination T-slot / vacuum ready bed built around solid box section & cast steel, you're assured of a super productive long term piece of kit! The list of customisation options is extensive and almost limitless.

We even include a license for Vectric’s super intuitive and easy to learn V-Carve Pro for your job creation/editing and post processing G-code creation (i.e. machining/cut file).

With full size specs in a smaller package the G1313R (1300x1300) offers great performance with a single tool ER20 (1/2″) 2.2kW air-cooled spindle, stepper drives and helical gears. The G1313R CNC machine is a popular option with schools, universities & serious home users given its ability to run on single phase power.

If you want a full sheet (1300x2500) or larger capacity, we offer bed sizes right up to the gigantic 6000mm x 2000mm -plenty of machining space with many upgrade options:

Upgrade options are:

- Bed size, Z axis height

- Pneumatic pop-ups

- Kerosene mist system

- Auto-oiler

- Quick tool change option, a single tool machine with push button tool changing.

- Spindle size/no. of tools - Auto Tool Changing (ATC) and 4 - 9 tool linear/carousel

- Vacuum pump size and type (if required) - 3kW to 7.5kW

- Voltage - 3-phase or 1-phase (within limits)

- Drive types - stepper or full servo

- 4th/rotary axis - either removable or permanently built in

- Boring head for flat end work - please ask. Italian, 2 head

- Aggregate drill / saw heads

Basically, we'll configure the best machine for your needs in the budget available!

Suitable materials:

- Plywood

- Hardwoods/softwoods

- MDF

- Acrylic/plastics

- Aluminium, Copper

- Common signage materials

- PCB boards

Included in the basic package is:

- 1 x G1313R CNC router, stepper driven, air (or water) cooled 2.2kW ER20 spindle

- 1300mm x 1300mm cut area, combination T-slot bed with vacuum (vacuum bed functionality requires an optional vacuum pump)

- Manual pump type reticulated oil lubrication system - delivers oil to all linear bearings with a simple pump action.

- Easy to use powerful DSP control system - doesn't require a PC connected to the machine.

- 1 x Toolkit containing basic maintenance and servicing tools

- Collets ER20: 3-4mm, 6-7mm, 8-9mm, 12.7mm

- Starter kit of cutters and engraving bits

- Basic 2.2kW dust extractor/collector, 100mm flexible hose & spindle mounted dust hood with brush.

Additional information

| Spindle type | Air cooled 3-phase (via Inverter) 2.2-9kW ER16-ER35. |

|---|---|

| Bed type | Alloy T-slot bed with machined urethane vacuum bed, multiple zones with facility to run dual vacuum pumps for backup and added performance. |

| Cutting area | 1300mm x 1300mm x 300mm (Z) through to 6000mm x 2000mm x 600mm (Z) …. and everything in between! |

| Drive type | Helical Rack/pinion drive |

| Control System | USB-loaded DSP offline control (no local PC required) |

| Command code | Standard postprocessor required (G-Code – we have tested these machines with V-Carve pro and Autodesk Inventor HSM/Fusion 360 and they run superbly) |

| Guide rails | Hi quality Taiwanese square linear guides on each axis. |

| Input voltage | Single-phase230V 50hz |